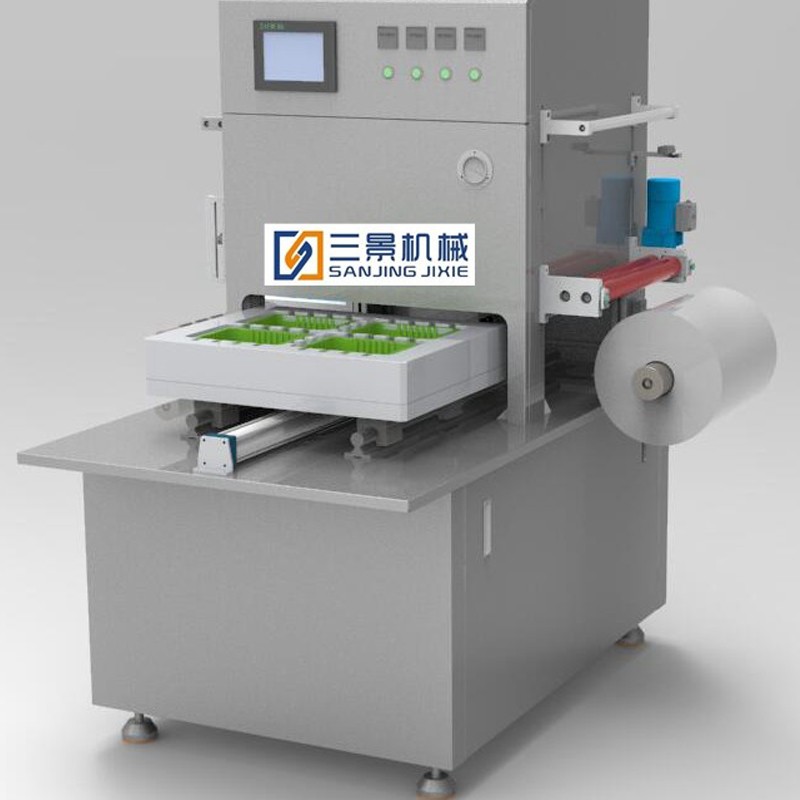

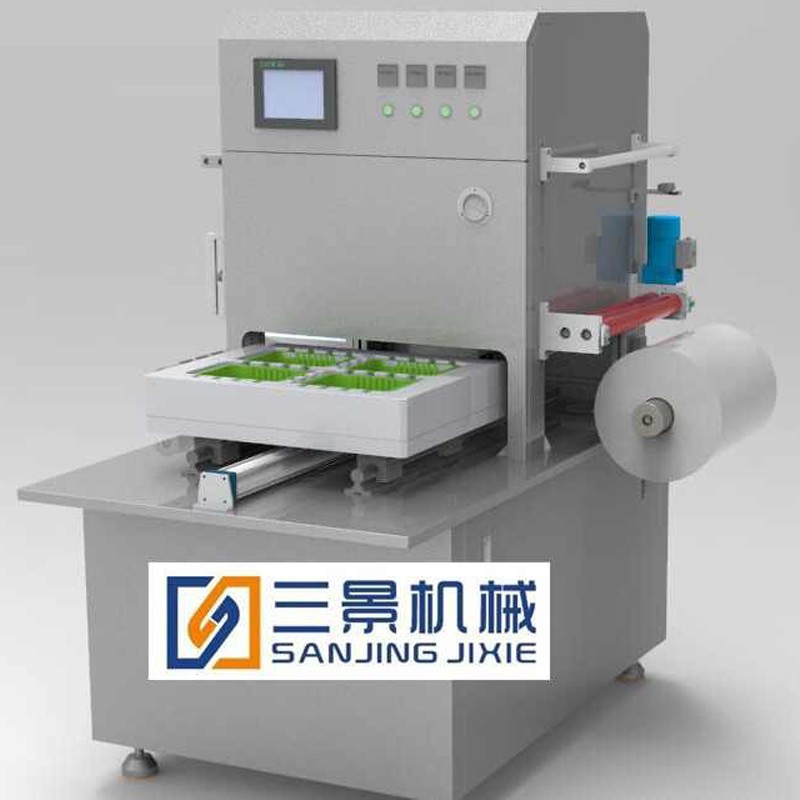

Semi Automatic Vacuum Skin Packaging Machine

Products in vacuum skin package, the shelf life is generally 30-35 days, up to 40 days. Vacuum skin packaging makes the product not only visible, but also within reach, customers touch the product through the packaging film above, just like the product itself.

-

Skin Packaging

Vacuum skin packaging is especially suitable for high quality products of meat and meat products, fish and seafood, poultry, convenience food, cheese, pastries, etc. Products that are prone to leak juice can be packaged with vacuum skin pack, as well as food products with longer shelf life requirements.

Email Details

Vacuum skin pack is characterized by its natural expression of quality, freshness, color and texture of the product, and keeps the product fixed on the bottom tray without pressure. The overall special top film, like a second skin effectively reducing liquid escape from the product. The vacuum skin pack can be easily opened through easy opening corners that can be integrated. Vacuum skin packaging can be painted, metallized, printed, embossed or labeled for attractive design while extending product shelf life. -

Codfish Vacuum Skin Packaging Machine

The Codfish vacuum skin packaging machine puts the packaged product on a special bottom plate (plastic tray, cardboard or plastic sheet), so that the special plastic top film covering the product is pressed against the surface of the product under the action of heating and vacuuming by the vacuum skin packaging machine, and is sealed together with the bottom plate. The products packaged inside are both well protected and show their natural form and appearance.

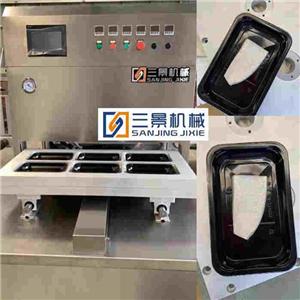

Codfish vacuum skin packing machine codfish vacuum skin packaging machinery vacuum skin packing equipmentEmail Details -

Skin Packing Machine

Vacuum skin pack could fix the product completely to the bottom tray which will anti shock, anti friction and shatterproof, so it will not be damaged by handling and transportation, especially suitable for the fragile or special-shaped products. Most seafoods are for export after vacuum skin pack, so such package avoid the damage to the product in the process of transportation and reduce the damage rate of the product.

Email Details -

VSP Skin Pack Machinery

The reason for wide and rapid development of vacuum skin pack is that the vacuum skin pack can pack special-shaped products includes vegetables, meat and poultry, aquatic products, toys, small tools, electronic products, etc. The special shrink film affixed to the packaging is generally transparent, sticking tightly to the product, which can show the appearance of the product. Due to the uniform contraction, the special shrink film has a certain toughness, which is not easy to tear at edges and corners. Vacuum skin pack can put the scattered products together. Now, thanks to the successful development of vacuum skin packaging machine, vacuum skin pack can extend the storage period of food and convenient to store. Vacuum skin pack has the advantages of overall seal, moistureproof, antifouling, antirust effect, easy to pile up in the open environment and saving warehouse area; Vacuum skin pack process and equipment are simple, universal and easy to achieve mechanization which save human resources and packaging costs. Vacuum skin packaging machine ensures low packing cost, wide range of applications, reliable performance and high efficiency which is about 10 times more than manual packaging.

Email Details -

vacuum Skin Packaging Equipment

In the field of packaging, what is the level and position of the paper packaging industry? With the deepening of the concept of low-carbon circular economy, I believe paper packaging will usher in a new opportunity for development.

Email Details

As manufacturers of vacuum packaging machinery, we should make full preparations and seize the opportunity.

We only choose BUSCH vacuum pump imported from Germany for all our machines to ensure vacuum quality and long-term stability and reliability of the machine. -

Vacuum Skin Packaging (VSP) Machinery

In the vacuum skin pack process, the upper special film fixes the product firmly in the bottome tray which is sealed to the entire surface of the product. Overall sealing along the pack provides additional packing protection, ensuring the appearance of the pack is attractive and extends the shelf life of the product, meanwhile leaking juices are avoided.

Email Details

Vacuum skin pack fixes the product in the predetermined position, preventing the damage of the product in the transportation process and preventing from damp deterioration. It will directly display the product because the film is transparent, It can also be packaged into groups which reflects its collection function. -

Vacuum Sealer Machine

The reason for wide and rapid development of vacuum skin pack is that the vacuum skin packaging machine can pack special-shaped products includes vegetables, meat and poultry, aquatic products, toys, small tools, electronic products, etc. The special shrink film affixed to the packaging is generally transparent, sticking tightly to the product, which can show the appearance of the product. Due to the uniform contraction, the special shrink film has a certain toughness, which is not easy to tear at edges and corners. Vacuum skin pack can put the scattered products together. Now, thanks to the successful development of vacuum skin packaging machine, vacuum skin pack can extend the storage period of food and convenient to store. Vacuum skin pack has the advantages of overall seal, moistureproof, antifouling, antirust effect, easy to pile up in the open environment and saving warehouse area; Vacuum skin pack process and equipment are simple, universal and easy to achieve mechanization which save human resources and packaging costs. Vacuum skin packaging machine ensures low packing cost, wide range of applications, reliable performance and high efficiency which is about 10 times more than manual packaging.

Email Details